Industrial machinery

(Labor-saving equipment)

-

1-1Dryer and drying

equipments -

1-2Dedicated machine

and equipments -

1-3Pharmaceutical medical

precision machinery

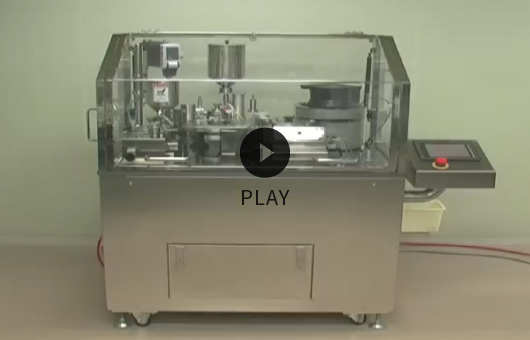

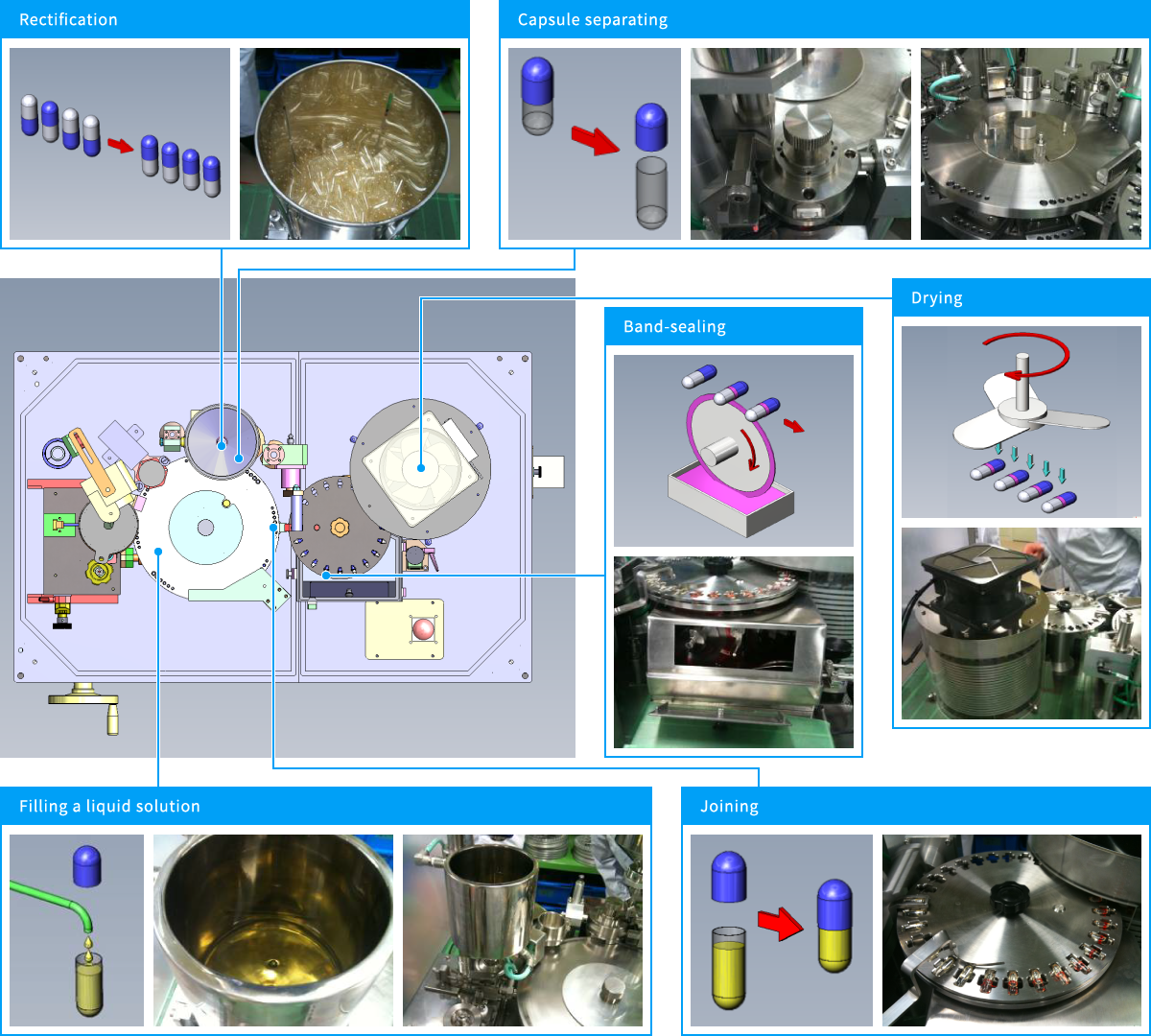

The fully automatic operation machine from liquid filling in a hard capsule to band-sealing with clean room specificaiton.

Capsule size are available in 00, 0el, 0, 1, 2, 3, and 4.(Capsule No1 size is standard, others are optional)

Filling unit could be filled from low viscosity (1 cp) to high viscosity (20000 cp). (From 50cp to 100cp is standard, other are optional)

Full automatic machine with band-sealing was launched as the world's first in 2008.

The fully automatic machine that fills a hard capsule two liquid solutinos and band-sealing with clean room specification.

Fully automatic machine is the world's first as the filling two liquid solutions.

Optional

>One liquid solution + one tablet solution

>One liquid solution + one granule solution

>Three lilquid solutions.

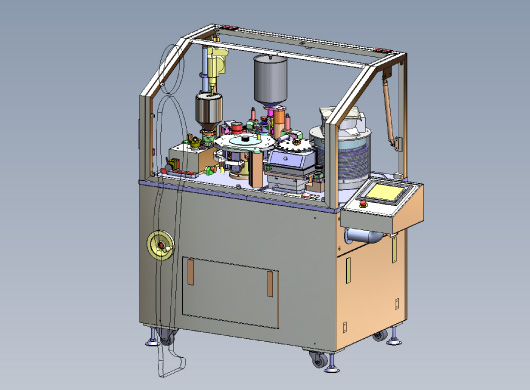

This machine was developed lab-scale [EKITEN] for medium-sized production machine.

It has the performance of the lab-scale [EKITEN] machine and it is consisted of 6 rows.

Full-automatic capsule filling machine from filling to band sealing.

It has a capacity of 18,000 capsules per hour.

(Capacity varies depending on the filling materials)

Capsule sizes:00,0el,0,1,2,3 and 4 is available Liquid solution's specification is a water-insoluble liquid and standard liquid viscosity could be filled from 50 to 100 cps.

Optional : Low-viscosity and high viscosity

Sales in-line type equipment from liquid fillng to band-sealing.

| Specifications | |

|---|---|

| 1.Filling solutions | Oil-based lilquid solution |

| 2.Capacity | 1,500Caps~3,000Caps/h |

| 3.available viscosity | 50CPS~100CPS (Optional : Low-viscosity and high viscosity) |

| 4.dimensions | W1,450mm×D715mm×H1,440mm |

| 5.Weights | 650kg (Included optional) |

| 6.Sales prices | ¥15,000,000~¥30,000,000 (Included optional ) |

| 7.Available capsule size (Fulled volume of liquid solutions) |

|

Operation Process

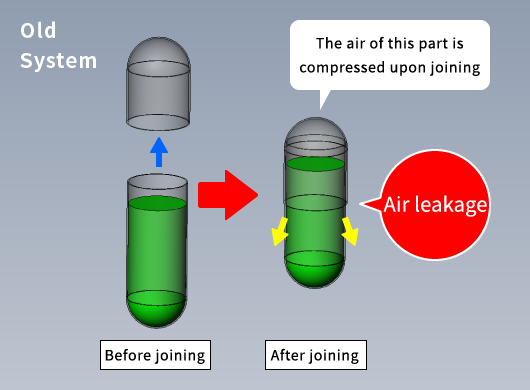

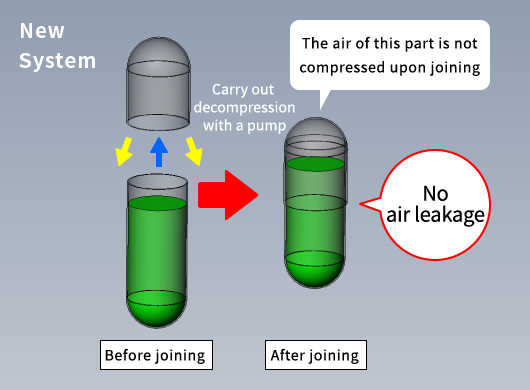

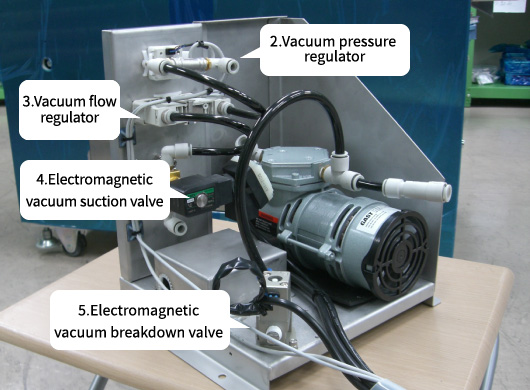

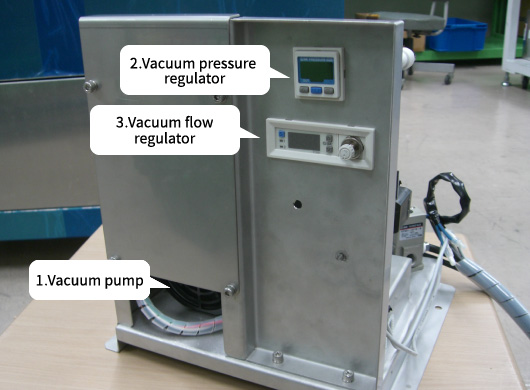

Development of a decompression system using vacuum technology

New vacuum decompressing system has solved the problem of increasing pressure in a capsule by decompressing the capsule's inside and its surroundings.

Mechanism of new vacuum decompressing system

-

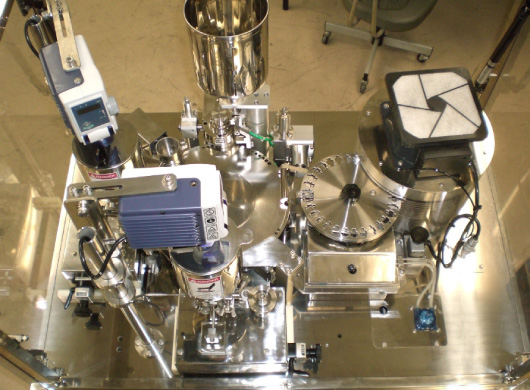

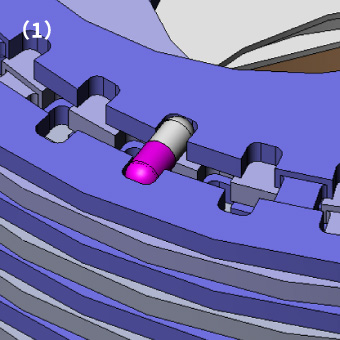

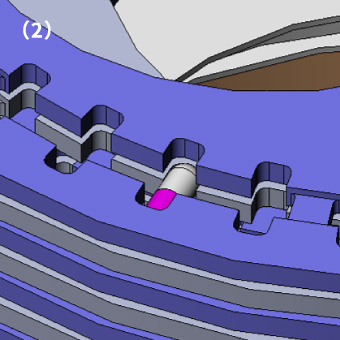

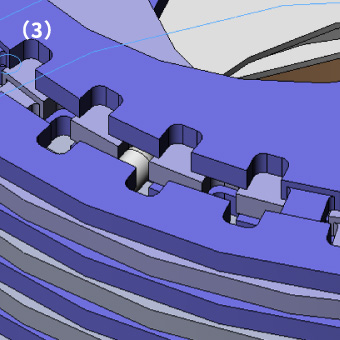

Inside the vacuum decompressing system unit

-

The vacuum decompressing system unit operation section

- 1.Operate vacuum pump and make vacuous.

- 2.Adjust the vacuum pressure

- 3.Adjust the vacuum flow

- 4.The suction timing is set in advance with mechanical parameters.

A vacuum suction valve is opened at a set timing to start vacuum decompression.

A vacuum suction valve is closed at a set timing to finish vacuum decompression. - 5.As soon as the suction valve is closed, the vacuum breakdown valve is opend to release the vacuum state.

A compact drying unit of high efficiency desing

Stack 20 drying plates and dry with blower fan while capsules drops between plates.

This keeps 400 capsules in the drying unit for at least 7 minutes and dries them.

Designed a compact and high efficiency drying unit.

Apply a band-sealing to the capsule and transfer it to the drying unit.

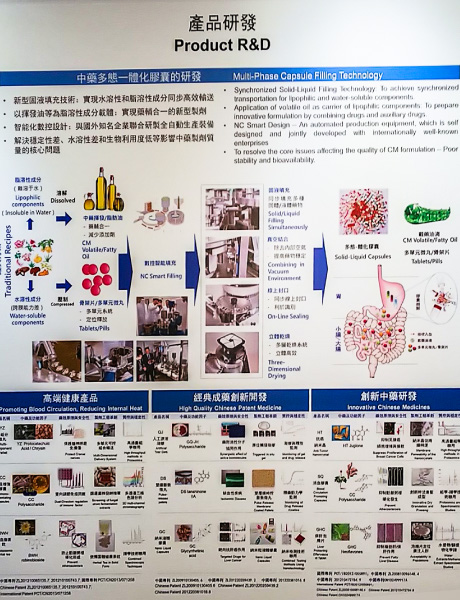

PROJECT

-

Explanation from the principal of Macau Univ. to President Xi Jinping (Picture1)

-

Research and Development facilities installed at Unversity of Macau

-

Study presentation using liquid filling and band-sealing machine

-

Capsule sample product

Research and Development of new medicines have been underway after EKITEN is indroduction at Unversity of Macau.

It is reported that drawing attention from President Xi Jinping (Picture1) in the ceremony of the 20th anniversary of Macau return in 2019.