Industrial machinery

(Labor-saving equipment)

-

1-1Dryer and drying

equipments -

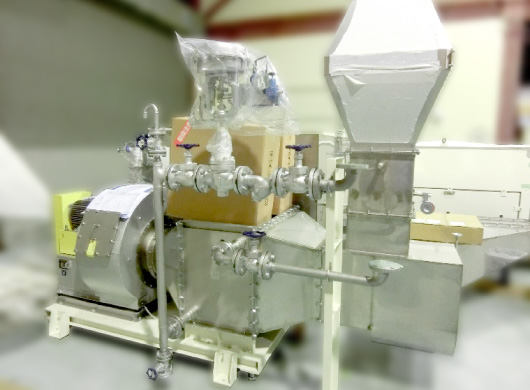

1-2Dedicated machine

and equipments -

1-3Pharmaceutical medical

precision machinery

In-line hardening furnace of clean room specification by electric heater as heat source.

Designed for mass production In-line high temperature hardening furnace for electric device.

Eight-row type production equipment with elevating of furnace upper body for maintenance.

In-line drying furnace with clean room specification by steam as heat source.

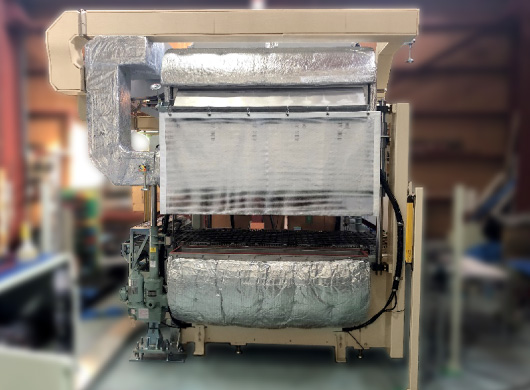

Drying furnace for lithium-ion battery's metal box.

Small size production facilities with a product width of 600mm.

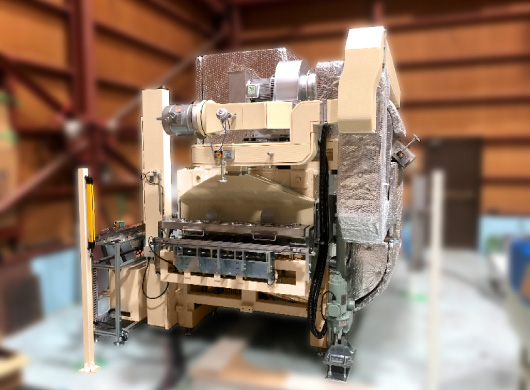

Batch type drying furnace for non-metal by electric heater as heat source.

A semi-automatic dryer in which the product is stored in a dedicated rack and put in manually by an operator.

There are five drying spaces, each of which can be operated independently.

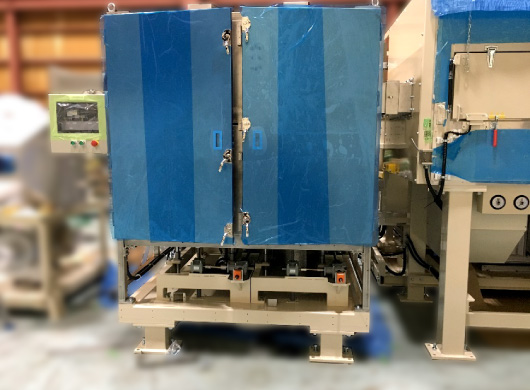

Batch type hardening furnace that holds products for on-vehicle parts at a set temperature while setting time.

Products are racked and put into a hardening furnace.

It would be automated in combination with a loader and unloader.

In-line furnace of clean room specification by electric heater and UV device as heat source.

In-line hybrid drying furnace for PET film.

Designed for a testing device for product development with a product width of 600mm.

Line type drying furnace for product of coating equipment.

Thick and coated products dried from inside due to the far-infrared effects that could be applied by ceramic heater as heat source.

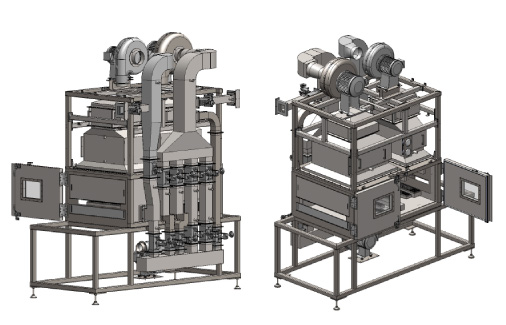

In-line furnace of clean room specification by electric heater and far-infrared ray.

In-line hybrid furnace for laminated filter.

Improved drying time from 60min in batch type to less than 4min in hybrid type.

It could be operated 24 hours a day by automatic of loader and unloader.

Design and manufacture of heat source for dryer, storing aerofin heaters, circulation fans and filter boxes.

Design and manufacture electric heater heat soruces and hybrd heat soruces.